Knowledge

Why does the dryer always leak from the evaporator

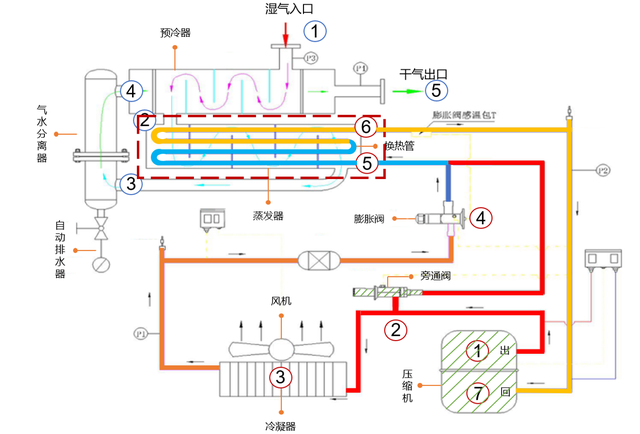

We all know that in addition to the aforementioned condenser, the precooler and the evaporator are also the main heat exchange containers for the heat exchange container in the refrigerated dryer.

So why is the chance of an evaporator leak much greater than the other two containers?

In fact, as long as we compare the processes and working conditions of the three containers, the reason will immediately emerge.

1. Welding process

Compare Evaporators vs Precoolers

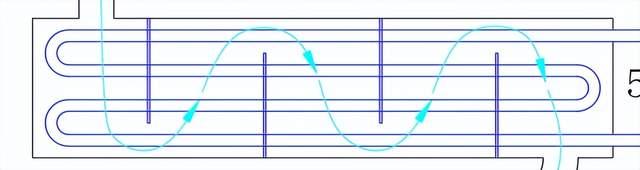

The heat exchange tube of the evaporator is driven by refrigerant, so the inlet and outlet are on the same side, which leads to the inevitable elbow of the heat exchange tube.

At this time, the expansion process needs to be used, and in the case of artificial processing, there must be defects in the process.

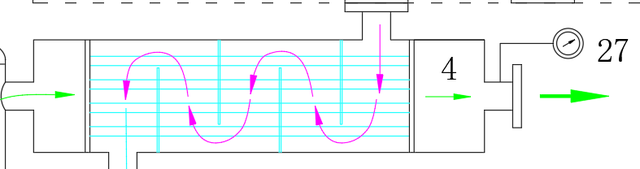

In contrast to the pre-cooler, its work only needs to transport the product gas to the outlet, so it only needs to use the straight-through form.

In short, the evaporator has increased the probability of future leakage in the manufacturing process.

2. Operating conditions

Compare Evaporators vs Condensers

The working condition of the evaporator is very bad, why do you say that?

Because the high temperature moisture enters the dryer, it will exchange heat with the refrigerant inside the evaporator. Saturated high-temperature moisture will condense a large amount of condensed water, and the inner wall of the evaporator will be slowly corroded by the humid environment, which will eventually leak.

Evaporators have hidden dangers of leakage in process and working conditions. Therefore, refrigeration dryer manufacturers should pay more attention to quality monitoring and provide reliable after-sales service when users need help.

FROM:gas drying encyclopedia

Specializes in the manufacture and production of compressed air purification equipment.

Specializes in the manufacture and production of compressed air purification equipment.