Knowledge

The working principle of compression heat regenerative dryer

Adsorption dryers generally adopt a double tower structure, one for gas drying and the other for adsorbent regeneration. At present, the commonly used adsorbent materials are activated alumina and molecular sieve. Activated alumina is sensitive to the temperature of the working medium. When the ambient temperature of the adsorbent reaches above 130 °C, the moisture content of the adsorbent is only about 1%, which is almost completely desorbed. The adsorption capacity of molecular sieve for moisture is higher than that of activated alumina at the same temperature, and the desorption of activated alumina is not as complete.

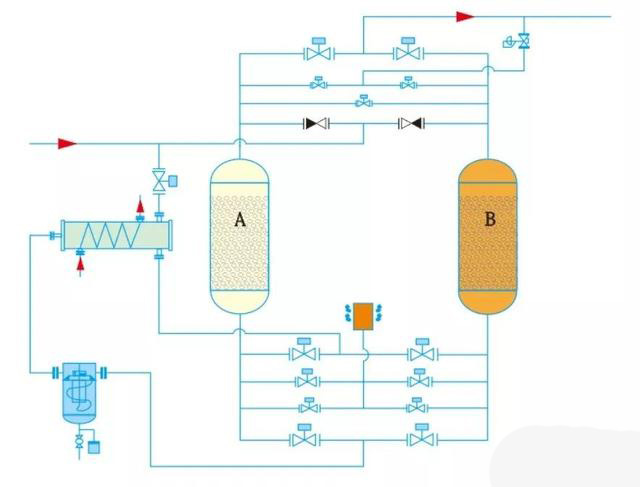

The adsorbent regeneration process is divided into 4 stages: heating-depressurization-cold blowing-pressure equalization. The adsorption tower and the regeneration tower are switched according to the control signal given by the dryer PLC. see picture 1.

The high-temperature compressed air (above 110°C) enters the dryer, and then directly flows into the regeneration tower, because the high-temperature compressed air is unsaturated, and it will vaporize the moisture stored in the adsorbent. The vaporized moisture is adsorbed by the unsaturated high-temperature compressed air and enters the The follow-up cooler of the dryer is cooled to about 40°C. At this time, the compressed air is in a supersaturated state, and a large amount of liquid water is precipitated, and the liquid water is discharged through the steam-water separator. The cooled compressed air enters the drying tower, and after reaching the dew point requirement, most of it is output to the compressed air pipe network for use in the supply workshop and each gas station, and a small part flows into the regeneration tower through the control valve to cool the adsorbent. The compressed air lost in this stage accounts for about 2% of the total air volume. Since the compressed air used for cold blowing is dry compressed air, the adsorbent can be desorbed twice. After the cold blowing process, this part of the compressed air is discharged through the muffler.

The regeneration tower and adsorption tower need to go through a pressure equalization process before switching. This process is controlled by the PLC control program of the dryer. Each switching means that the dryer goes through a complete working cycle. The control methods generally include dew point control and time control.

The compressed air entering and leaving the dryer is a continuous process, and the switching of the two towers of the dryer is an intermittent process, so the two are in an asynchronous state. When the regeneration tower is in the process of cold blowing, the high-temperature compressed air entering the dryer must be bypassed and directly enter the aftercooler and steam-water separator, and then enter the drying tower. These processes must be implemented through the dryer control program.

Specializes in the manufacture and production of compressed air purification equipment.

Specializes in the manufacture and production of compressed air purification equipment.