Knowledge

The difference between vacuum frozen dryer and air frozen dryer

Alias: Frozen air dryer, freezer frozen dryer, compressed air dryer, etc.

The frozen air dryer has become the current main air drying and purification equipment. It is widely used in various pneumatic equipment, pneumatic tools, paint paint, food packaging, light spinning, chemical industry and other industries in industrial production.

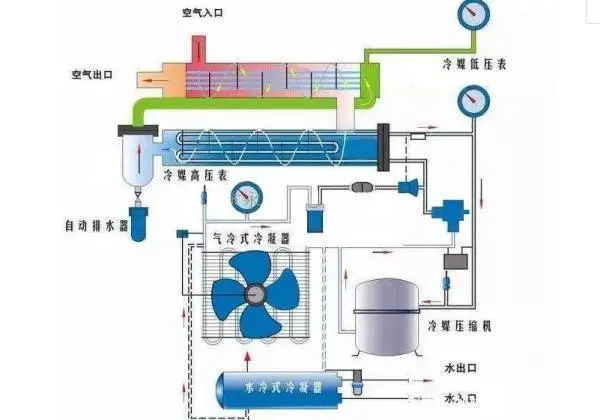

Principles: The humid and high temperature compressed air flow into the front cooler (special -specific), and the heat exchanger is inflow and the heat switch discharged from the evaporator after the heat dissipation is used to reduce the temperature of the compressed air entering the evaporator.

The frozen compressed air dryer is cooled by cooling, which is the purpose of compressing the water vapor in the air into a droplet, thereby achieving the purpose of reducing the moisture content. The liquid droplets that are condensed are discharged by the automatic drainage system. As long as the environmental temperature of the downstream pipeline of the dryer exit is not lower than the evaporator exit dew point temperature, the phenomenon of secondary exposure will not be generated.

General workflow:

The air process -compressed air enters the pre -cooler from the air entrance to preliminary cooling, flows into the refrigeration system evaporator, further cools from the refrigeration system. The cooling compressed air is returned to the heat exchanger to warm up, leaving the frozen dryer through the air exit.

Refrigeration Process -Refrigeration is compressed by a cooling compressor in a high -temperature and high pressure liquid state. The liquid refrigerant in high temperature and high pressure state passes (air -cooled or water -cooled) condenser to cool down and cools into a medium temperature high -pressure state. Filtering, the refrigerant becomes a low -temperature and low -pressure air fluid mixed state through the effect of capillary. After entering the heat exchange of the evaporator and the heat of the heat, the refrigeration work is completed and returned to the refrigeration compressor for circulating work.

Vacuum frozen dryer

Alias: Frozen dryer, freezer dryer, frozen drying equipment

After booting, put the material into the freeze -drying room for freezing. The freezing process of the material is to take the vacuum system for vacuum and take away some of the water; The surface is frozen, and after the frozen requirements are met, the heating system is heated and dry to the material. Bring the water contained in the material in the freezing capture box by drawing vacuum to freeze the material frozen and dry requirements.

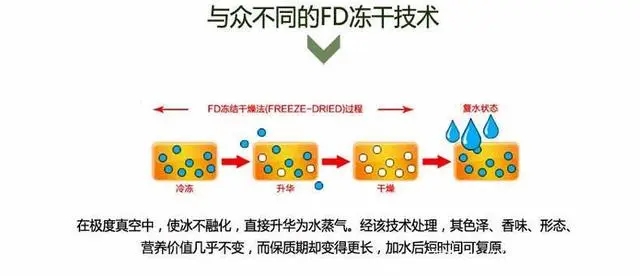

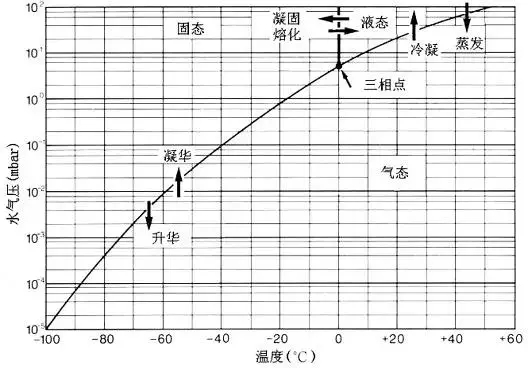

Frozen dryness refers to the process of removing moisture or other solvents from frozen biological products. The sublimation refers to the process of solvents, such as water, like dry ice, without liquid, from solid state to a process of directly to gaseous. The product obtained by freezing and drying is called lyophilizer, which is called frozen dried.

General process process:

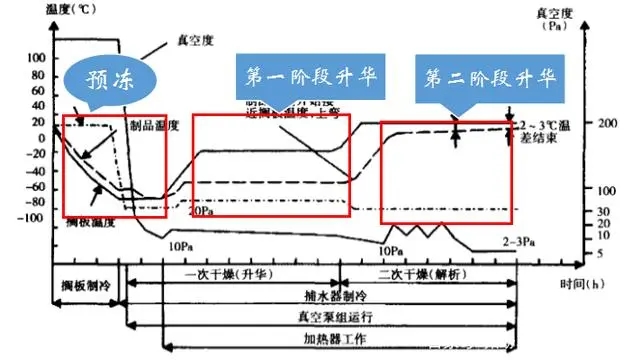

Pre -frozen stage: First freeze the water in the material into ice, so that the dry materials have the same form before drying. The pre -frozen temperature must be lower than the co -crystal point of the material.

Sublimation and drying stage: Dry in the first stage. After pre -frozen, the vacuum is vacuum. At this time, the water in the object is sublimated directly from the ice to the steam. Due to the absorption of heat in the process of gasification, heating should be given through the shelf. Due to the pressure difference between the drying box and the condenser, the water vapor continues to enter the condenser and the sublimation is continuously proceed until the sublimation phase ends. In this process, the temperature and pressure should be controlled below the common point of the object, so that the ice is not melted.

Analysis of drying stage: In some cases, the second stage of dryness needs to be performed. Some objects contain water attachment (such as water on the wall of the internal capillary of the object and the water adsorbed on the polar gene). This water is not frozen. In order to remove this part of the water, it is necessary to provide sufficient heat to heat up the object. As long as it does not cause it to deteriorate due to overheating (generally up to 30-50 ° C), it is also a vacuum environment.

Vacuum freezing and drying are only one of the ways to freeze and dry, but because the vacuum freezing and drying application is more extensive, especially in schools and scientific research units, it is often mixed with freezing drying with vacuum frozen drying.

FROM:百家号/拓纷真空冷冻干燥机

Specializes in the manufacture and production of compressed air purification equipment.

Specializes in the manufacture and production of compressed air purification equipment.