Knowledge

Key performance indicators of compressed air dryer

The purpose of this article is to point out the performance indicators (KPI) that can help maintain the performance of compressed air dryer and eliminate failure.

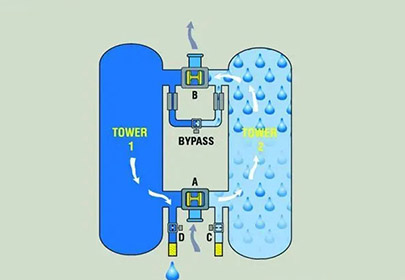

Stress dew point

First of all, we need to introduce the most important indicator of judging compressed air quality. The PDP of the compressed air should be monitored at the exit of each dryer and the next section of the next section of the compressed air convergence from multiple dryers. The combination PDP measurement of multiple dryers is important, with two reasons. First of all, you only need a small amount of wet air to destroy the PDP of the compressed air after the processing of other dryers. It will not meet the requirements. By synchronizing all the dryers during adsorption, they can switch the adsorption/regeneration tower at the same time, which can minimize the peak effects of the dew point.

All dryer type KPI

The following projects will affect the performance of all types of compressed air dryer.

- Liquid oil and water (condensed liquid)

- Entry flow

- Intake air temperature

- Entry pressure

- Ambient temperature

- Water inlet temperature and flow

- Dirty/dirt cooler

- Unqualified automatic drain pipes and blocking drain pipes

Liquid oil and water (condensed liquid)

Generally, after the compressed air is cooled in the cooler of the air compressor, it is 100% saturated. When it flows through the connection pipe between the air compressor and the dryer, it will cool and condense water and water in the pipeline Oil. The condensed water and oil volume depends on the temperature difference between compressed air and the environmental temperature in the pipeline and the distance between the compressor and the dryer.

Many frozen dryers do not have a front or rear filter during installation. Therefore, the condensed water and oil will block the dryer and their internal separators, thereby preventing the dry air from drying the air, and the separator cannot remove it from the system from the system. Essence

A adsorption dryer is usually installed in the front section of the dryer, but this usually cannot prevent moisture and oil from passing the filter element, nor can it be completely prevented from condensing water and oil downstream of the pre -filter. For example, the flow level of filters is usually maximum 50 PPM W/W, including water, oil, gas solution and solid. Any air pollutants higher than 50 PPM W/W will reduce the rated capacity of the filter. When they exceed 200 PPM W/W, moisture and oil may be around the filter element. If the water reaches the desiccant, it will reduce the capacity of the dryer to maintain the pressure dew point; if the liquid oil reaches the desiccant, it will destroy the desiccant. As far as possible, the pre -pre -filter installation of the fog or a suitable wet air receiver can prevent the filter from overloading. In addition, if the ambient temperature is low enough, the wet air receiver and pre -filter, and the pipeline between the pre -filter and the entrance of the dryer should heat up.

Entrance conditions (flow, temperature, pressure, environment/cooling water temperature)

The capacity of the dryer is directly related to its entry pressure, and the air and environment/cooling water temperature of the entrance; therefore, the air flow of the dryer processing air flow will continue to change with the changes of these indicators. Monitor the inlet pressure and entry temperature of the dryer, and then allow engineers to calculate the current dried flow flow according to the environment/cooling water temperature, and then compare it with the inlet flow of the dryer monitoring. Note: The entry pressure and temperature of the dryer should be monitored at any pre -filter downstream, and as close to the dryer/tower as much as possible.

Although the inlet flow exceeding the capacity of the dryer will prevent it from maintaining the standard pressure dew point (PDP), too low traffic will reduce the efficiency of certain frozen dryers and certain water separators containing cooler. Decreasing the efficiency of the water separator will cause water and/or oil to be brought into a desiccant that is brought into a compressed air system or adsorption dryer. In addition, diversion and some compressed heat regenerative dryers require a minimum flow to ensure the regeneration of the desiccant.

Cooling water temperature, flow and cooler export air temperature

Monitoring cooling water temperature is particularly important for compressing heat and adsorption dryers, because the hot air for regenerative desiccant should be cooled to 37C to keep the dryer of the -40C pressure dew point. Because the close temperature of most used tube shell heat exchangers is -9C, they need 29C or lower cooling water temperature, so the temperature of the cooling water temperature exceeds 29C compressed thermal recycled adsorption dryer may not be installed Keep a pressure dew point of -40C.

Dirty/dirt cooler

The dirty dirt in the frozen dryer is a common problem that causes abnormal stress dew points. For tube shell heat exchangers, the exit air temperature of the cooler will notify the equipment management personnel problems. Monitoring of cooling water temperature and flow can let us know whether the cooler needs to clean or water supply.

Unqualified automatic drain pipes and blocking drain pipes

The water separator, wet air receiver, dryer pre -filter, and the water -free dried dryer and certain types of regenerative dried dryers in the water compressor after the air compressor are installed in the air compressor. Essence The automatic drainage pipe may not be opened or closed. When the automatic drainage pipe cannot be opened or blocked, the moisture or oil will flow back to the compressed air system or desiccant. Generally speaking, from the design point of view, the drainage pipe should be stainless steel. Some electric "airless losses" automatic drainters are used to provide local or remote alarms, and some pneumatic automatic drainors provide local or remote counter.

Other KPIs of the Regenerative Adsorption Dorgee

The following projects are specific to the performance of the regenerative dryer.

- Blew

- Back pressure of the dryer offline tower

- Valve failure

- Recycling temperature of heating dryer

- The filter on the drum fan of the heating fan is dirty or back pressure

Blew

The formula displayed below is suitable for the blowing traffic required for the "heat -free" regenerative dryer. The formula shows that the required blowing flow directly changes with the flow of the inlet and indirectly changes with the pressure of the inlet. This means that if the flow flow of the inlet is the same as the rated flow of the dryer and the inlet pressure is lower than 6.8BAR, it is necessary to increase the scanning flow.

Qp = (q x 1.15) / ((P + 14.7) / 14.7)

QP = Blowing and Sweeping (SCFM)

Q = Entry flow (SCFM)

P = Entry pressure (PSIG)

Correctly setting and sweeping traffic is usually solved by setting it to the minimum expected pressure and peak traffic, so there is no need to monitor the blowing traffic; however, because we cannot just rely on the blowing pressure gauge on the dryer, it is recommended to monitor the blowing pressure. In order to reduce energy consumption and maximize the production of compressor production, if the peak flow is lower than the amount of flow of the dryer, some suggestions will be recommended to reduce the scanning flow.

Decaddy dryer valve failure

When the valve of the adsorption dryer fails, the compressed air from the attached tower can flow into the regeneration tower, and then flow out of the exhaust valve. Valve faults may dump the entire capacity of the upstream air pressure, which leads to the suspension of the factory. In addition, when the valve of the dryer fails, but there is sufficient air compressor capacity to maintain the system pressure, the increased gas production and the fault of the dryer cannot be found in time. Therefore, it is recommended to monitor the inlet and export flow of the regenerative adsorption dryer, and install a brake valve in the blowing exhaust pipe road. The valve will trip and issue an alarm when the system pressure is too low. Some manufacturers' dryer control devices turn off the dryer and exhaust valve at low pressure; however, because these valves are often faulty as other dryer valves, it is best to install a cut -off valve.

Regeneration temperature

The regeneration temperature of the adsorption dryer should be monitored because they need the minimum regenerative temperature to maintain the pressure dew point of compressed air. In addition, it is recommended to monitor the operating power of the heater, especially on the internal drying dryer.

The filter on the drum fan of the drum fan of the heating fan is dirty or back pressure

With the increase of the voltage drop of the filter of the drum fan, the blowing flow decreases, so the pressure decrease should be monitored. The failure valve failure will also generate back pressure on the drum firger; thereby reducing its flow, so the discharge pressure of the virus should be monitored.

Other projects that may affect the performance of regenerative drying machines

Energy -saving control on the adsorption dryer -runs the regenerative desiccant dryer in its energy -saving mode can save energy and extend the service life of the desiccant; however, it does affect the pressure dew point of the system.

The dew -point monitor on the adsorption dryer faults can prevent the dryer switching adsorption/regeneration tower running in the energy -saving mode; therefore, it is very important to maintain the dew point monitor regularly.

Desiccant wear -The life of the desiccant in the regenerative adsorption dryer depends on the integration method of the dryer and the system, the quality of the desiccant, and the operation and maintenance of the dryer. In most cases, the life of the regenerative desiccant is roughly 1 year, which means that it needs to be replaced once a year.

ARTICLE SOURCE:SIKELUOKONGYAJI

Specializes in the manufacture and production of compressed air purification equipment.

Specializes in the manufacture and production of compressed air purification equipment.