Knowledge

The principle of suction dryer

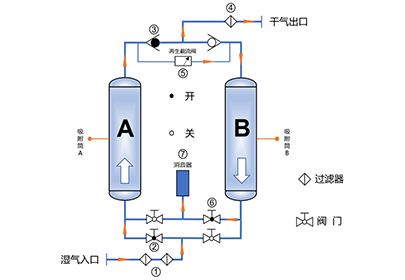

As for the suction dryer, we will take the easiest-to-understand "heatless adsorption dryer" as an explanation, which is simpler than the cold dryer.

The A and B cylinders of the suction dryer will work alternately, so only the process of A adsorption and B regeneration will be described here.

(1) The moisture that needs to be dried enters the pipeline from the lower inlet and passes through two precision filters

(2) The gas passes through the valve (2) opened on the left, and then enters the A tower from bottom to top for adsorption and drying

(3) After the gas comes out from the upper part of the A tower, a large part of the dried gas passes through the valve (3) and goes towards the outlet

(4) Finally, the gas passes through the precision filter (4), and after the filtration is completed, high-quality dry gas is obtained for the user to use

(5) After the gas comes out from the upper part of the A tower, a small part of the dried gas passes through the (5) regeneration shut-off valve, and enters the B tower for regeneration from top to bottom.

(6) Moist gas passes through the open valve (6)

(7) Finally, it is safely discharged from the (7) muffler

Specializes in the manufacture and production of compressed air purification equipment.

Specializes in the manufacture and production of compressed air purification equipment.