Knowledge

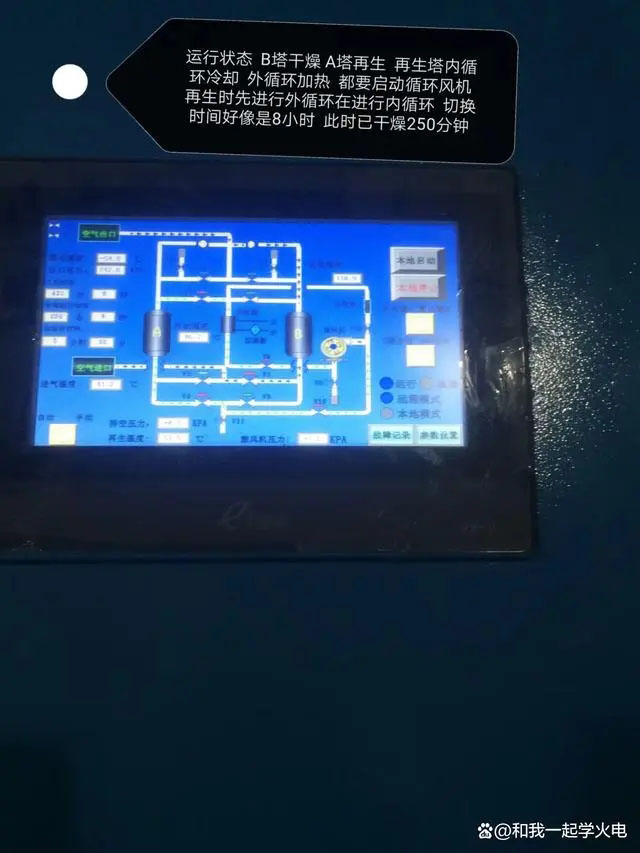

The dryer of the air compressor, the introduction and operation of the drying and regeneration process

The main function of the dryer is dry and compressed air, because many pneumatic doors and precision instruments are prohibited from entering wet air, otherwise it will damage the equipment.

The regeneration of the dryer is divided into two parts: the first stage: the foreign air circulates from the fan. After the electric heating, enter the tower that needs to be dry, such as the A Tower regeneration, the B tower is dry, the foreign air enters the A tower, and it will be adsorbed to the A tower. The water on the inner desiccant evaporates and is carried and discharged. The second stage: Close the external gas source, circulate the air from the fan, and pass the cooler to reduce the temperature inside the A tower.

The dryer of the dryer: If the A tower is switched from drying to regeneration, the B tower is dry, and the first step is to stop the A tower circulation, that is, stop the fan operation. The A tower is dry. The third part is regenerated after the pressure in the B tower is released.

Precautions:

1. During regeneration, the temperature of the closed water of the inner circulation cooler is <40 ° C, otherwise the window may damage the leak due to thermal expansion and contraction.

2. The dryer is stopped, that is, no regeneration or drying. The drying tower is automatically switched to dry and regeneration for 8 hours. After the adsorbent of the dryer can be dry, it cannot be dried. A dry tower can run for 8 hours without saturation (after regeneration).

Author:和我一起学火电

Specializes in the manufacture and production of compressed air purification equipment.

Specializes in the manufacture and production of compressed air purification equipment.