Knowledge

Principles and relevant requirements of the configuration of the medical air compression system

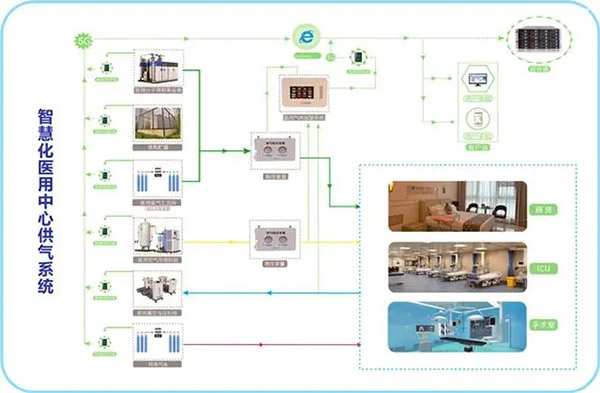

The medical air compression system consists of compressed air stations, pipe network systems, ward terminal equipment. After the compressed air output of the air compressor is qualified by drying and multi -stage filtering, it is provided to the end of the air. According to the relevant provisions of the "GB50751-2012 Medical Gas Engineering Technical Specifications", the medical air compression system must meet the relevant configuration principles and requirements.

Medical air supply sources should be composed of intake mucoping device, compressor, rear cooling, gas storage tank, air dryer, air filtration system, decompression device, stop valve, etc., and should meet the relevant requirements: First, medical air When the supply source is in a single failure state, it should be able to continuously supply gas; the second is to set up a spare compressor. When the maximum flow of single compressor faults, the remaining compressors should still meet The air compressor should be used to use the type of oil -free lubrication; the fourth is to set up anti -flow device.

Secondly, the medical air compression system should also comply with the following regulations: First, the air compressor's air intake device should comply with relevant regulations; second, the medical air filtering system should comply with relevant regulations; third, the equipment, pipelines, valves, and accessories of medical air equipment; The link should comply with relevant regulations; fourth, the medical air supply source control system, monitoring and alarm shall comply with relevant regulations; fifth, the medical air supply source shall set up emergency spare power supply.

In addition, the location of the station building of the medical air compression system should be available near the nearest gas pipeline as much as possible, and stay away from the location that will cause air pollution, such as the medical attraction of the system exhaust, the exhaust port, the biogas gas,, the biogas,,, the biogas,,,,,,, Sewage treatment stations, etc. Medical air pressure station buildings should have good ventilation, stay away from pollution sources and various exhaust emissions ports, and must not be built with system stations with medical centers.

In short, according to the actual demand for air gas consumption in the hospital, the overall plan design, scientific equipment configuration, standardized construction management, professional operation and maintenance management and other services should be provided to achieve the construction and management of one -stop medical air compression systems for the hospital.

Specializes in the manufacture and production of compressed air purification equipment.

Specializes in the manufacture and production of compressed air purification equipment.